WHEEL SPECIFICATIONS:

Wheel Style: MV Forged MR-101

Diameters/Widths: F19x9” – R20x12”

Series: Aero

Construction: 3 Piece Forged – Lightweight

Weight Reduction: Pocketing | Undercuts

Finish: Satin Jet Black

Outer Lip Finish: Gloss Jet Black

Cap/Badge: Carbon Red | Gloss Twill Carbon Badges

Hardware Material/Finish: Stainless Steel | Gloss Black Hardware

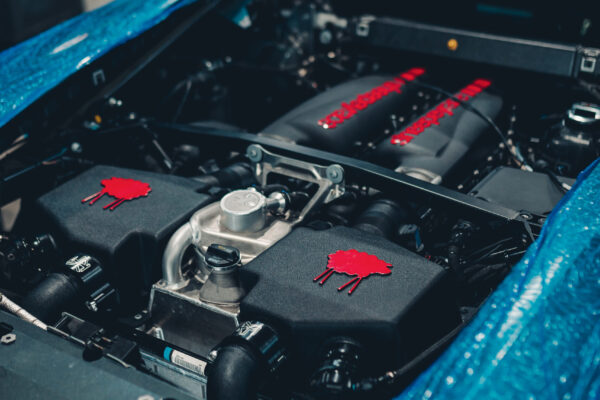

Dealer: Sheepey Race | @sheepeyrace

As many of you should know by now, our good friends at Sheepey Race are known for creating some of the fastest Lambos on the West Coast. This Huracan in particular opted for Sheepey’s highest package which is stage 3, good for around 1800 horsepower. There’s obviously a whole slew of parts that go into this kit mechanically to ensure the car can handle almost three times the power over stock. However, all of that doesn’t mean much if you can’t put the power down.

The easiest way to add grip to your car is by using a wider wheel and tire setup over stock. A major benefit of choosing 3-piece wheels is the ability to build custom offsets and sizes specific to your needs. This Huracan is currently sitting on our MR-101 Aero Series® in a 19×9 front and 20×12 rear setup. The wider track width allows for a wider tire, which again is important to ensure the most grip possible. Finished in a Satin Carbon black Face paired up with Gloss Carbon Black Lips and Hardware. The wheel finish against the forged carbon of the 1016 kit is a very subtle and clean contrast that gives this Huracan a sinister look.